CLT A-Frame House

CLT A-Frame House

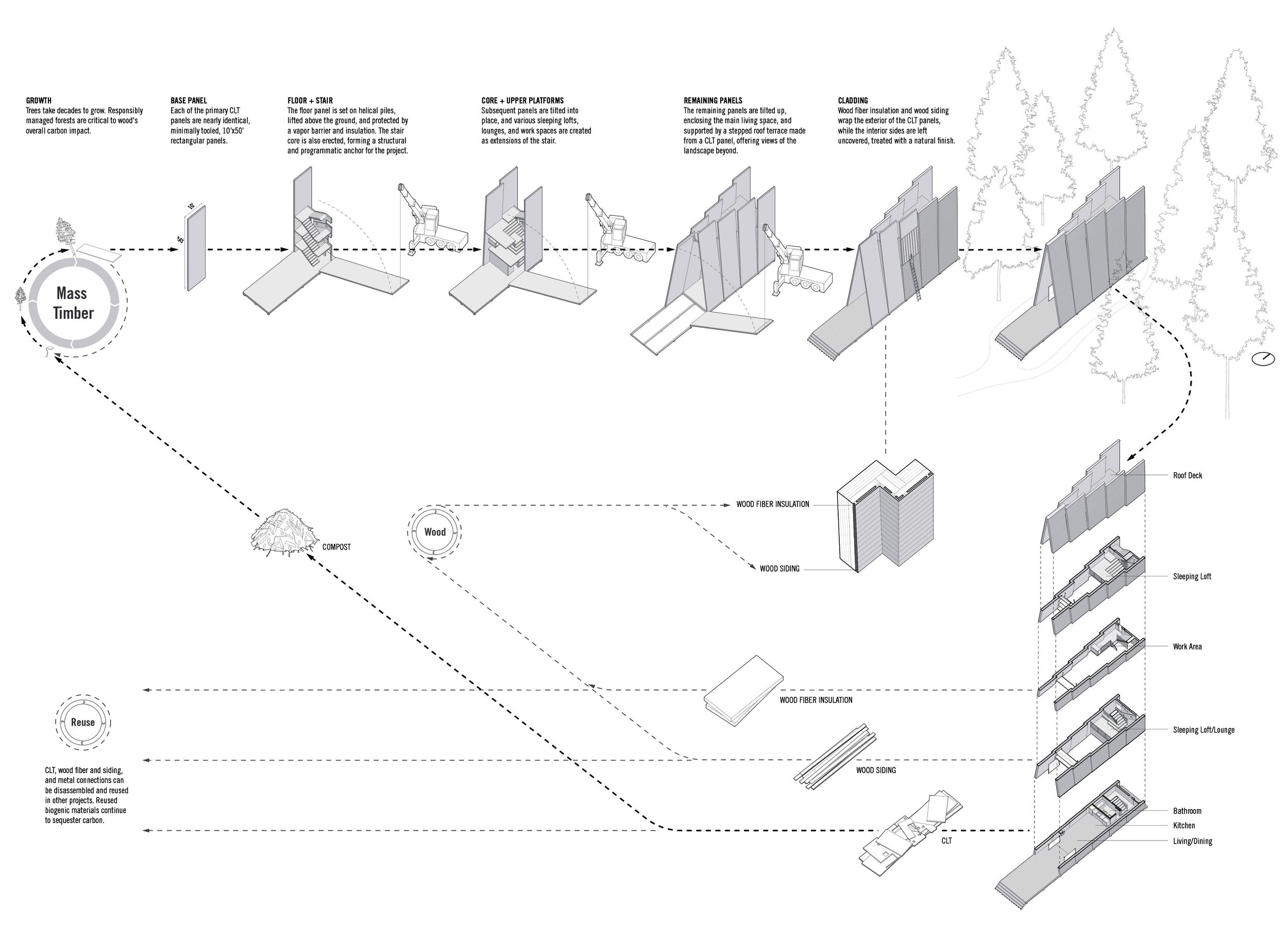

This project uses the unusual size of the standard cross laminated timber (CLT) panel to rethink the A-frame cabin. Rather than cutting CLT to replicate the box shape of a typical rectangular house, this project exploits the elongated dimensions of a typical CLT panel to form a tall structure. The manufacturing dimensions of CLT are set by the size of the glue and press bed which are designed to create very long mass timber panels at a given width. For this house, standard panels are used with minimal tooling and the assembly process is based on the efficiency of minimal parts to maximum effect. Here, 10 pieces of 5-ply CLT panels, each 10’ x 50’ long, oriented vertically, are used to build and shape the house. The resulting tall space is used to reorganize domestic life and engage the conditions of a wooded site.

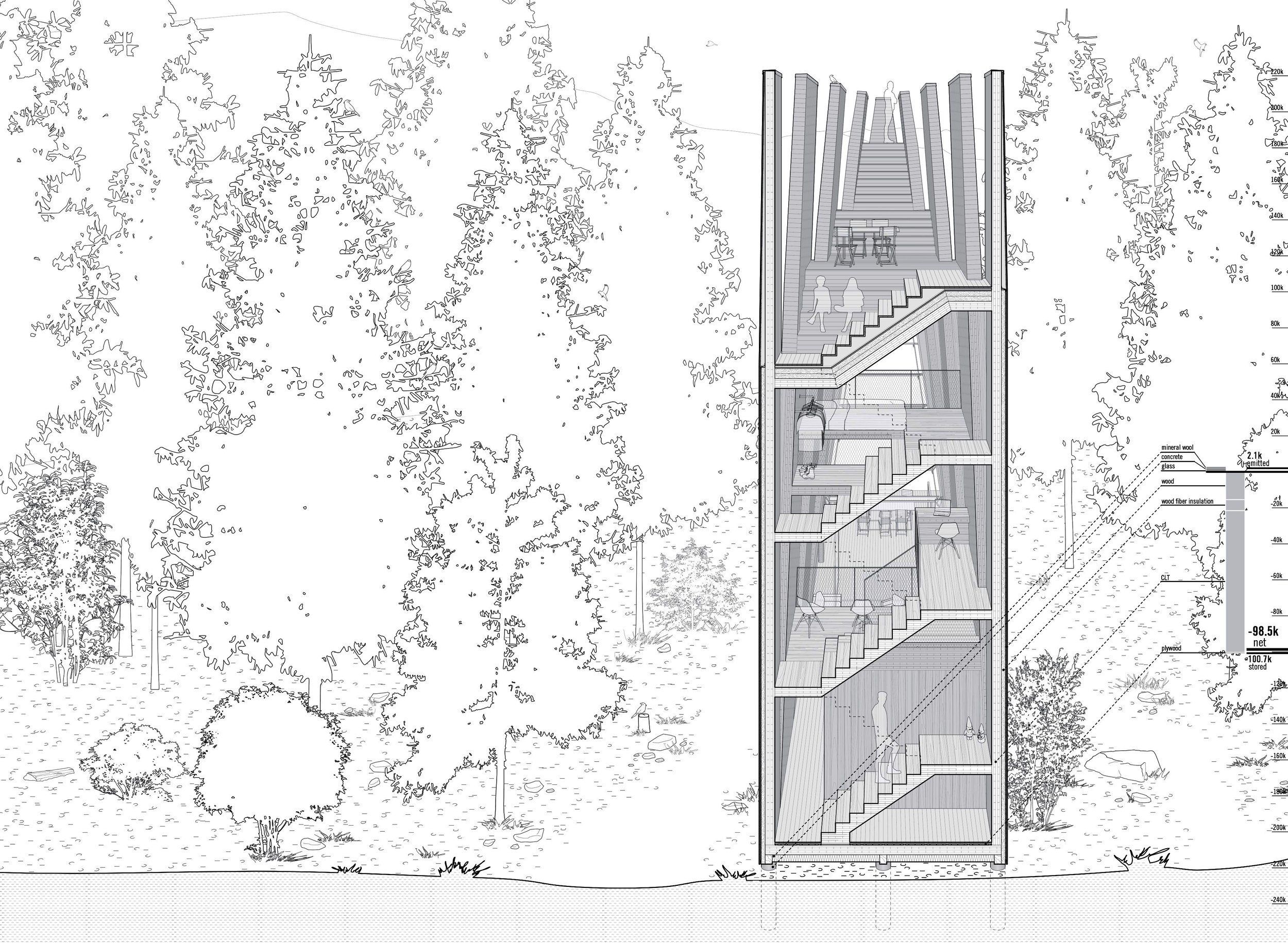

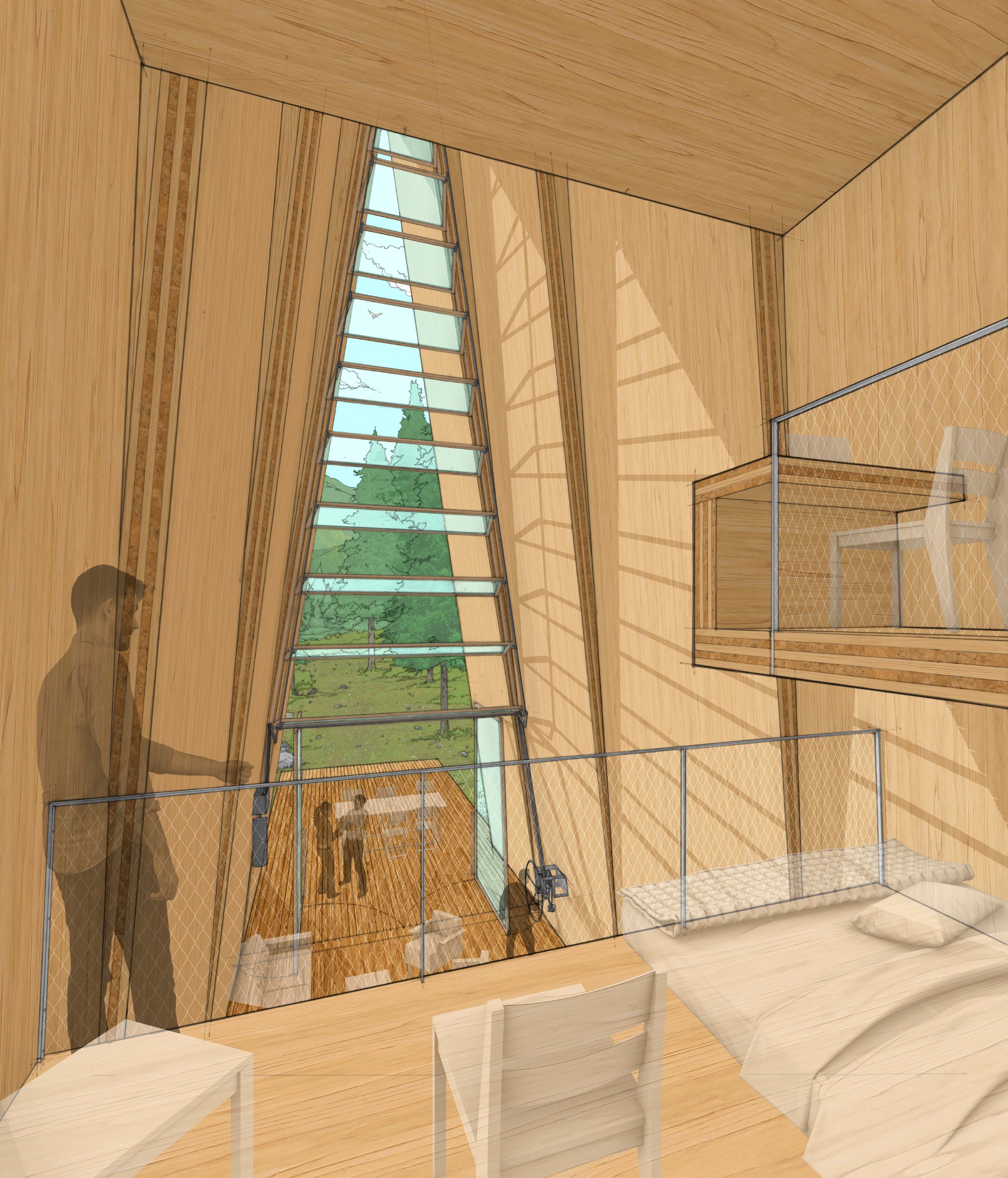

A single panel forms the plan of the house with five pairs of panels tipped into place on the east and west sides. The northernmost set of panels anchor into a prefabricated staircase made from CLT and serves as the structural core of the project, providing necessary shear resistance. The front pair of panels form an isosceles triangle, and define an A-frame facade. Three pairs of panels fill in the middle and are staggered equally in their angle of orientation from the triangle in the front to the rectangle in the back. Horizontal planks of CLT extend from the staircase to create spaces for sleeping, working and gathering, organized to work within the tall spaces formed by the pairs of tall timber planks. A serrated and stepped CLT panel forms the roof enclosure and provides an occupiable roof deck with integrated seating located high among the treetops.

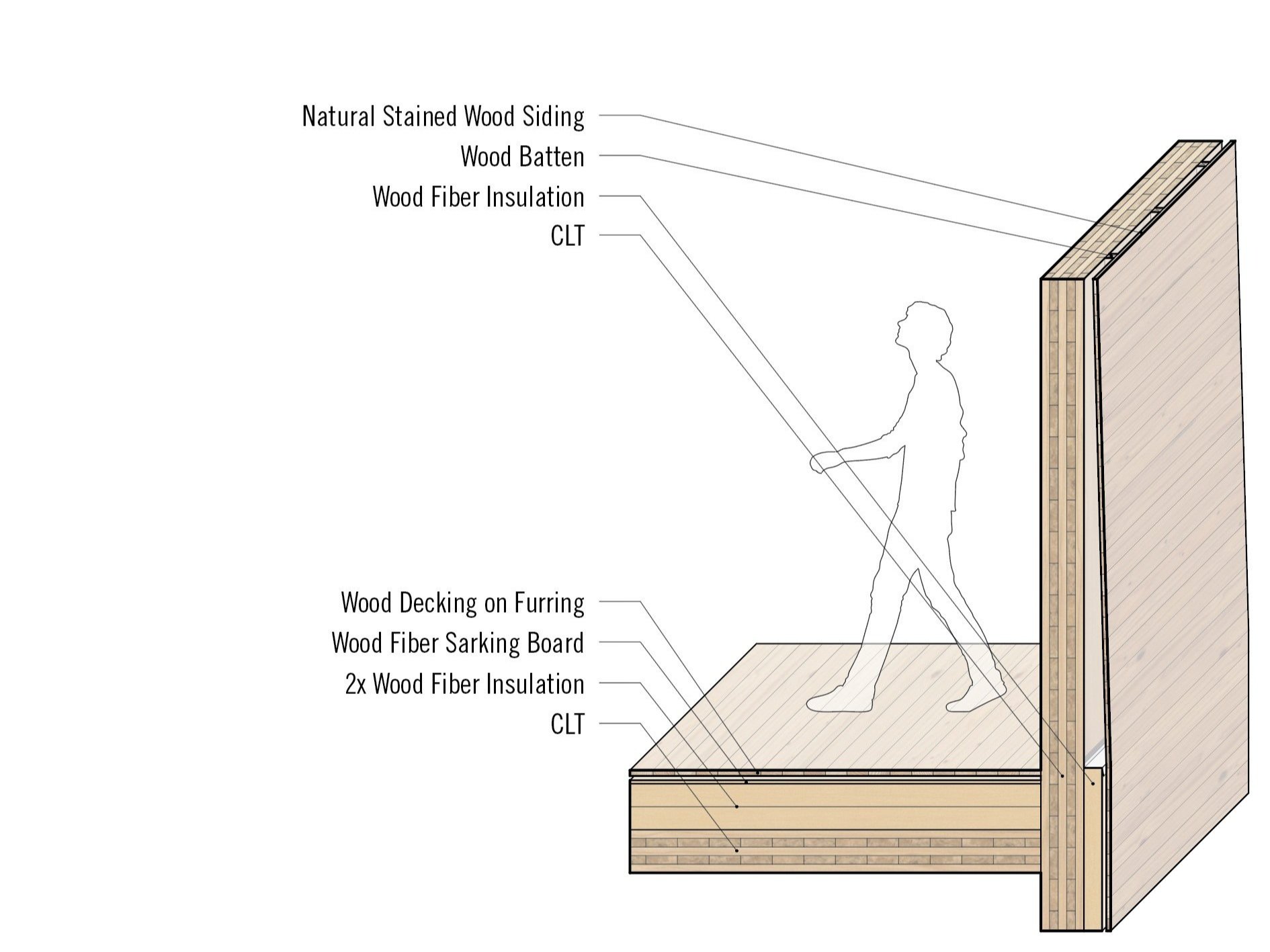

Wood-based building materials are used throughout to complement the CLT structure, creating a single material wall, and maximizing the sequestered carbon of the house. Wood fiber insulation mixed with paraffin provides the thermal and vapor barrier on the outside of the CLT. Wood planks set on timber purlins comprise the exterior rain-screen. At the front, a louvered glass facade can be adjusted to control ventilation, using the interior height to maximize cooling from stack effect while ensuring solar gain during winter months. On the inside, the CLT forms the interior surface, and is treated with natural oils for protection and durability. Use of slender pier foundations create a minimal foundation, lifting the CLT away from the ground, and limiting disturbance of the soil on the site. As such, the house is designed to be nestled in a forest setting, with the speed of the prefabrication assembly process of the CLT limiting the impact on the land, and the vertical reach of the A-frame embracing the surrounding timber landscape.

Type

Credits

Five Biogenic House Designs: Paul Lewis, Marc Tsurumaki, David J. Lewis, Celia Chaussabel, Kyle Reich, Tengku Sharil Bin Tengku Abdul Kadir, and Danial Mahfoud.

Link to Five Biogenic Houses Booklet